The Ultimate Guide To China Injection Molding

Table of ContentsWhat Does China Injection Molding Do?Indicators on China Injection Molding You Need To KnowChina Injection Molding for BeginnersThe Buzz on China Injection MoldingHow China Injection Molding can Save You Time, Stress, and Money.China Injection Molding Things To Know Before You Buy

Small Design Mistakes Have BIG Costs with Shot Molding Upfront costs tend to be really high due to layout, testing, and also tooling requirements. If you are going to generate components in high volumes you desire to ensure you obtain the layout right the first time. That is more challenging than you could assume.

Await High Tooling Prices for Shot Molding Tooling is practically a task per se and only one stage of the whole shot molding procedure. Prior to you can generate a shot molded part you first need to create and also model a component (possibly using CNC or 3D printing).

See This Report on China Injection Molding

And also normally after considerable screening in both of the previously mentioned stages, you get to shot mold a component. As you can imagine, every one of the version required to get the device correct before automation calls for both money and time. It is uncommon that you would prototype an injection molding tool.

This is exceptionally tough and also in most cases could imply needing to junk the tool (or part of the tool) totally as well as begin again. In various other instances you could be able to weld metal right into the dental caries that is unwanted. Uniform Wall Density is Essential Shot molding requires consistent wall density.

Maintaining wall surfaces from being too thick is necessary to avoid disparities in the cooling process causing defects like sink marks - China injection molding. A great general rule is to keep wall surfaces less than or equal to 4mm thick. The thicker the wall surfaces the more worldly you will certainly use, the longer the cycle time will be as well as the higher your cost per component will certainly be.

China Injection Molding Things To Know Before You Get This

For an example of a large shot built part, take into consideration the buying carts at Target. Although the equipment exists to mold large pieces (e. g. 1000 heap presses about the dimension of a train's caboose), utilizing it is really pricey. Therefore, things that are bigger than a normal injection molding device's capacity are most typically produced in several items.

CNC is limited to the travel and size of the bed in the milling device while large 3D published components often need to be published in several pieces and after that adhered with each other. Huge undercuts need knowledgeable style to be prevented and can usually include prices to the project. So Is Injection Molding the Right Option for My Task? Prior to you seek to generate a component by means of shot molding take into consideration a few of the following points.

9 Easy Facts About China Injection Molding Explained

From there, you'll intend to establish the number of components created at which you anticipate to recover cost on your financial Website investment (think about the costs of style, screening, manufacturing, assembly, advertising and marketing, and circulation along with the expected price factor to buy). Construct in a conventional margin. And also do not forget regarding entrance expenses.

Make sure you recognize their website this crucial point in advance. Next, Let's Talk Style Factors to consider When it comes to part style, you desire to make the component from the first day with shot molding in mind. Simplifying geometry as well as reducing the number of components early will certainly pay rewards in the future.

Some Known Details About China Injection Molding

It is also beneficial for settled prototypes that are utilized for customer and/or product testing. Prior to this late stage in production, nonetheless, 3D printing is far more affordable and flexible for products in the beginning of design.

Contents Injection molding is one of the most typically utilized manufacturing process for the construction of plastic components. A wide array of items are made utilizing shot molding, which differ substantially in their dimension, complexity, as well as application. The injection molding procedure calls for the use of a shot molding maker, raw plastic material, as well as a mold.

The steps in this process are described in greater detail in the following area. Shot molding is used to generate thin-walled plastic components for a large range of applications, among one of the most usual being plastic housings. Plastic helpful hints housing is a thin-walled room, frequently requiring several ribs and also managers on the interior.

The Ultimate Guide To China Injection Molding

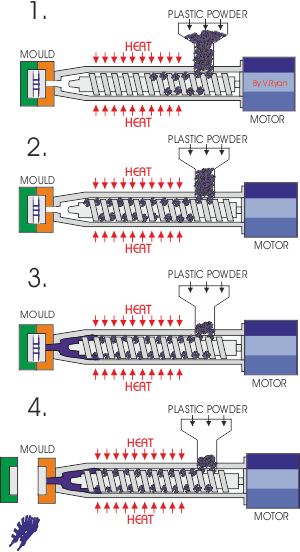

Refine Cycle The procedure cycle for injection molding is really brief, commonly between 2 seconds and also 2 minutes, as well as includes the adhering to 4 phases: Clamping - Before the shot of the material into the mold and mildew, both halves of the mold and mildew must initially be firmly nearby the clamping device.

The hydraulically powered securing unit presses the mold and mildew halves with each other and also exerts enough force to maintain the mold and mildew securely closed while the material is injected. The moment required to close and also secure the mold depends on the device - bigger devices (those with higher securing forces) will need even more time.